Cold Rolled Sections With Bespoke Capabilities

Decades of experience backed up with in-depth expertise in the cold roll forming process have enabled MCRS to grow at an exponential rate.

It is this laser-like focus on our industry, combined with how we perfect our processes, and the level of support and guidance we deliver to every single MCRS customer that has helped perfect both our services and the products we produce.

Backed up by a high quality record, MCRS re-thinks engineering processes to manufacture cold rolled sections which excel in their application.

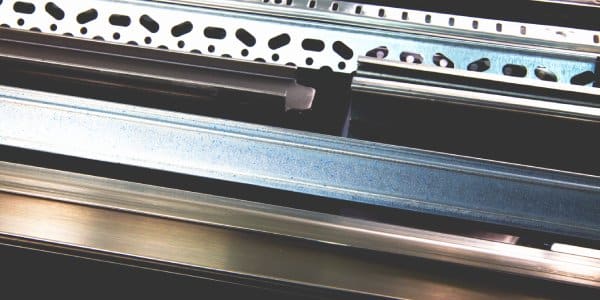

MCRS utilises up to 30 roll stands to form a variety of cold rolled profiles. Our roll forming capabilities include:

Got a question?

Talk to the experts today, get the support that speaks your language...

MCRS Bespoke Cold Rolling Services

MCRS works with both ferrous and non-ferrous materials, as well as high strength and coated materials, to provide our customers with a truly bespoke service ministering to customers’ unique specifications.

Whilst lead times for custom sections will vary depending on the complexity of bespoke tooling, the engineers at MCRS are considerate of our clients’ project timescales.

Our experience providing cold rolled formed solutions to a number of industries has enabled us to continue to exercise and evolve our practises.

Industries include:

Cold Roll Forming West Midlands

At Midland Cold Rolled Sections, we have the capacity for roll-forming processes, which include but are not limited to;

- Metal pre-pierce

- Metal fabrication

- Assembly of cold rolled sections

- Working with cut-off technology

Our extensive knowledge and expertise in cold rolled sections in the West Midlands allows us to be able to offer the following roll-forming shapes;

- Yacht fenders

- Racking uprights

- Stainless steel tracks

- Floor & frame profiles

What is Cold Roll Forming?

Hot Rolling

Hot rolling is a metalworking process that involves heating metal above its recrystallization temperature to deform it plastically during the working or rolling operation.

Cold Rolling

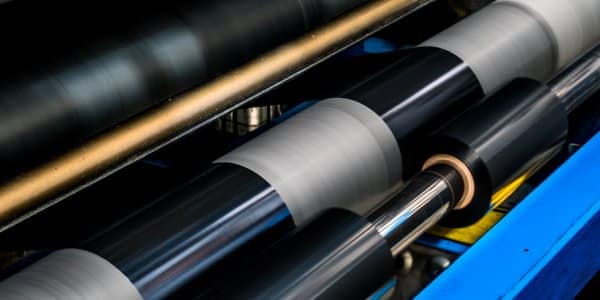

Cold rolling passes metal through rollers at temperatures lower than its recrystallization temperatures. The metal is compressed and squeezed, which increases its yield strength and hardness.

Shape Rolling

Steel shape rolling is a laborious process that necessitates great heat and force. The metal is reheated to around 1200°C before being continuously fed through rollers to draw the desired dimensions.

Roll Bending

Roll bending involves pushing an extrusion around three different rolls in a triangular shape. The rolls are adjusted to form a precise angle, ranging from 0 to 360 degrees, and can roll horizontally or vertically.

Flat Rolling

Flat rolling is the most basic type, with a rectangular cross-section of the starting and ending material. The material is fed between two rollers known as working rolls, which rotate in opposite directions. The gap between the two rolls is less than the starting material's thickness, causing it to deform.

Controlled Rolling

Controlled rolling improves steel properties to levels comparable to those of more highly alloyed or heat-treated steels. Controlled processing conditions refine the austenite structure and produce fine ferrite grains.

Advantages and Disadvantages of Cold Roll Forming

Advantages of Cold Roll Forming

Cold rolling has many unique advantages and can frequently be preferable to other options. Firstly, due to the lack of high temperatures during the process, you get a better surface quality for various applications.

Another benefit is that cold-rolled steel has tighter tolerances. Simply put, it has a higher tolerance level, e.g. it is thinner without losing any of its strength which is unique to this process.

With the cold rolled forming process, you get multiple options, including; full hard, half hard, quarter hard, and skin rolling. However, it is worth noting that only full cold rolled processes can offer you up to a 50% reduction in thickness to give the tightest tolerances.

Disadvantages of Cold Roll Forming

While there are many advantages of cold roll forming, there are some disadvantages too. As there is no heat during cold rolling, the steel isn't as malleable as when heat is used, making it harder to shape.

It can also be more expensive than heat rolling which can be costly to businesses; however, the advantages often make up for this by giving a more robust product with a better surface finish.