Metal Fabrication & Assembly

MCRS’ continued investment into machinery, and our curiosity to develop innovative and effective manufacturing methods, have catalysed our growth and leading position within the cold roll forming industry.

The comprehensive fabrication and assembly services offered by MCRS provide our customers with an end-to-end in-house service, as we personally guide customers through their manufacturing journey.

At MCRS, we pride ourselves on our excellent customer relations, with the experience and knowledge of our engineers enabling us to advice the best solutions for the unique problems our customers face.

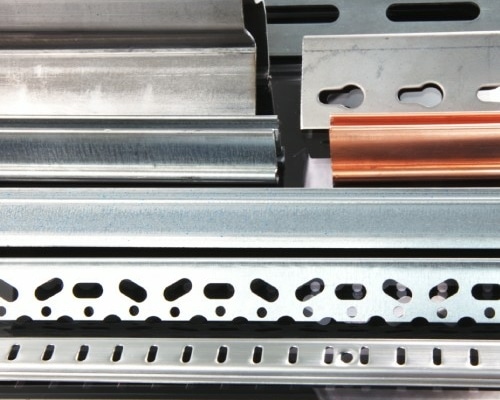

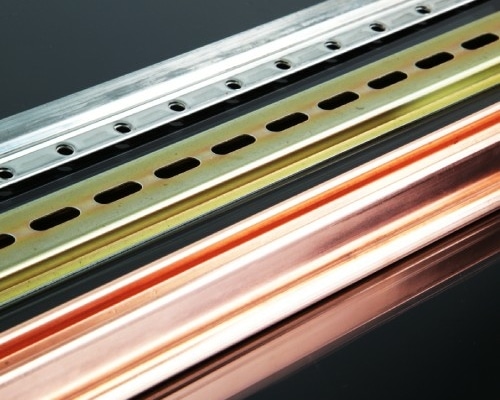

Alongside our fabrication and assembly services, MCRS utilises up to 30 roll stands for cold roll forming operations. As specialists in cold roll forming, MCRS are able to work with and deliver:

Got a question?

Talk to the experts today, get the support that speaks your language...

What is Metal Fabrication?

Fabrication and assembly are two processes that are often used together in manufacturing. Fabrication is the process of creating a product from raw materials, while assembly is the process of putting together pre-made components to create a finished product. In this article, we will discuss the purpose of metal fabrication, the various processes that can be involved, and the benefits of using fabricated cold rolled sections.

What is The Purpose of Metal Fabrication?

The primary purpose of metal fabrication is to shape raw materials into a useful product. This can involve cutting, forming and joining different parts together as well as machining processes such as drilling and tapping. The end result can be anything from simple items like nails or screws to more complex products such as automobiles, aircrafts and ships.

What Processes Can Be Involved in Metal Fabrication?

There are several different processes that can be involved in metal fabrication depending on the type of product being created. These include:

Cutting is the process of trimming material down to its desired size while forming involves shaping it by bending or hammering it into a specific shape. Welding is the process of joining two pieces of metal together using heat and pressure, while heat treating involves hardening or softening the material. Finally, finishing involves polishing, coating and painting to give the product its desired appearance.

Benefits Of Fabricated Cold Rolled Sections

Cold rolled sections are a popular choice for metal fabrication due to many reasons:

Advantages & Disadvantages Of Metal Fabrication

Advantages Of Metal Fabrication

Metal fabrication provides a number of benefits including increased strength, improved safety, cost savings and environmental friendliness. Fabricated metals are often stronger than cast or molded materials due to the processes involved in their production. This can lead to improved safety as well as longer product lifespans. In addition, metal fabrication can be more cost effective compared to traditional casting methods due to less material wastage and fewer errors during the production process. Finally, metal fabrication is generally an environmentally friendly process since it produces fewer emissions and uses recycled materials whenever possible.

Disadvantages Of Metal Fabrication

One disadvantage of metal fabrication is that it can require specialized skills which may limit the number of people who can perform it successfully. Additionally, fabricating metals can be more time-consuming than other manufacturing processes, especially for complex products. Finally, because the fabrication process requires precise measurements and accuracy, it can result in costly mistakes if not carried out properly.

Advantages & Disadvantages Of Metal Assembly

Advantages Of Metal Assembly

Metal assembly is the process of putting together pre-made components to create a finished product. This method offers several advantages over traditional fabrication processes since it cuts down on production time as well as material wastage. Additionally, metal assembly allows for greater flexibility when designing products since components can be easily swapped out or adjusted during the process. Furthermore, it can help reduce labor costs since fewer people are required to assemble a product compared to fabricating one from scratch.

Disadvantages Of Metal Assembly

While there are many advantages to metal assembly, it also has some drawbacks. The first is that the scope for design and customization is limited since components must usually be pre-made in order to assemble them. Additionally, an assembly line can be less efficient than traditional fabrication processes if parts or tools need to be moved between workstations frequently. Finally, because the process requires precise measurements and accuracy, mistakes can still occur during assembly unless care is taken throughout the process.