Chassis Manufacturing

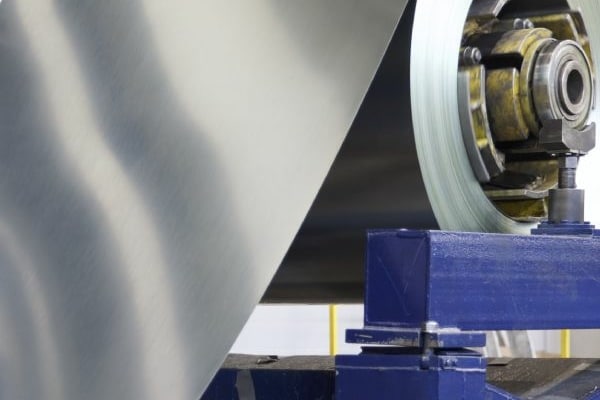

MCRS is a steel manufacturing company that specialises in cold roll forming, the best steel rolling process for chassis and substructures. Cold roll forming allows us to manipulate steel bars while retaining their natural strength and durability. It’s how we create caravan chassis.

MCRS collaborates closely with manufacturers to design and develop chassis for caravans, parks, and mobile homes. Whether you need a new chassis for a bespoke project or an upgrade for a perfectly good vehicle with a faulty chassis, talk to our expert team. Our chassis are high-quality and come with guarantees.

Got a question?

Talk to the experts today, get the support that speaks your language...

Caravan Chassis

Static caravans need chassis. A chassis is the backbone of the caravan; it forms the foundation of the caravan and performs a few key functions, such as integrating the stabiliser and the jockey wheel. There are two types of chassis, single-axle and double-axle chassis foundation.

Static caravan chassis can be painted steel, part galvanised, or fully galvanised. Static caravan chassis need to be inspected regularly to ensure the mobile home has a solid and reliable foundation throughout the year. Make sure chassis are inspected before the winter season.

The type of chassis a static caravan has depends on the weight capacity and suspension system of the caravan; most caravans are between 10-12 feet in length, but they can be as large are 45 feet in length. There is always an option to change or modify your static chassis.

Mobile Home Chassis

Static caravan chassis are solid but simple; they don’t need to sustain the pressures of driving on the road since they are always transported. Mobile homes are different. A mobile home is a motorised vehicle with an axle that must support the vehicle's suspension, brakes, and wheels.

As with static chassis, mobile home chassis can be painted steel, part or fully galvanised; this determines how well the steel stands up to weather conditions. Unlike static chassis, mobile home chassis have suspension and braking systems to create comfortable driving conditions.

The size of the mobile home chassis depends on the size of the vehicle. Typically, mobile home chassis can be single or multiple axles, depending on the dimensions of the vehicle. Inspecting and maintaining a mobile home chassis regularly is necessary for safety and to prevent rusting.

Park Homes Chassis

Park homes are bungalow-style homes about the size of a static caravan, though they are usually larger than that. Park homes tend to be located in caravan parks or park home sites; they offer a secure, cost-effective place to live. They are popular, especially with older people.

Park home classification is based on the home's mobility. If it can be transported in one or two parts, it is considered a park home. For that reason, park homes also have chassis that need to be understood, inspected, and maintained to ensure the structural integrity of the residency.

Park home chassis configurations come in single or twin-axle designs; this depends on the size, weight, and usage of the dwelling. Twin-axle configurations support larger park homes and provide better weight distribution. Single axle designs are better for smaller homes and parks.

People in the market for a park home or park home chassis to upgrade an existing home should consider some critical factors. It’s important for the park home to be stable and safe when static and support driving during transportation. Check the weight capacity, suspension, and braking.

Our Chassis Manufacturing Capabilities

Since chassis form the foundation of the static caravan, park home, or mobile home, they are worth investing in. Think of a mobile home chassis as the foundation of a residential home; they need to be solid and reliable. Like foundations, chassis also need to be inspected regularly.

Our expertise lies in utilising cold roll forming, a process that involves manipulating steel at low temperatures to create exceptionally strong parts. This method allows us to produce consistent and repeatable parts and structures that meet high standards and quality requirements for various mobile chassis. We specialise in the production of static home chassis specifically designed for other manufacturers.

MCRS creates chassis in-house using their cold roll forming infrastructure and processes. Although experts focus on static caravans, mobile homes, and park homes, we also create chassis for transportation, housing, and industrial applications to meet specific requirements.

At MCRS, we specialise in working with manufacturers who require caravan, park home, or mobile home chassis. Whether you need to create a new chassis for a project or upgrade an existing mobile home, it’s best to speak to our team of experts for a custom-made solution. Don’t compromise on quality when it comes to your home’s chassis; invest in quality and learn how to maintain the structure.

Galvanised Chassis Manufacturing: Lead Times and Finishes

Not only can MCRS develop high-quality chassis for your project, but we can create them in a short time. We can build a chassis in a matter of hours, allowing us to offer a 7-10 day turnaround time when you book with us. All chassis are cold rolled for strength and galvanised post-fabrication to protect them against adverse weather conditions over the long term. Get in touch with the expert team at MCRS to discuss your project and receive a competitive quote.